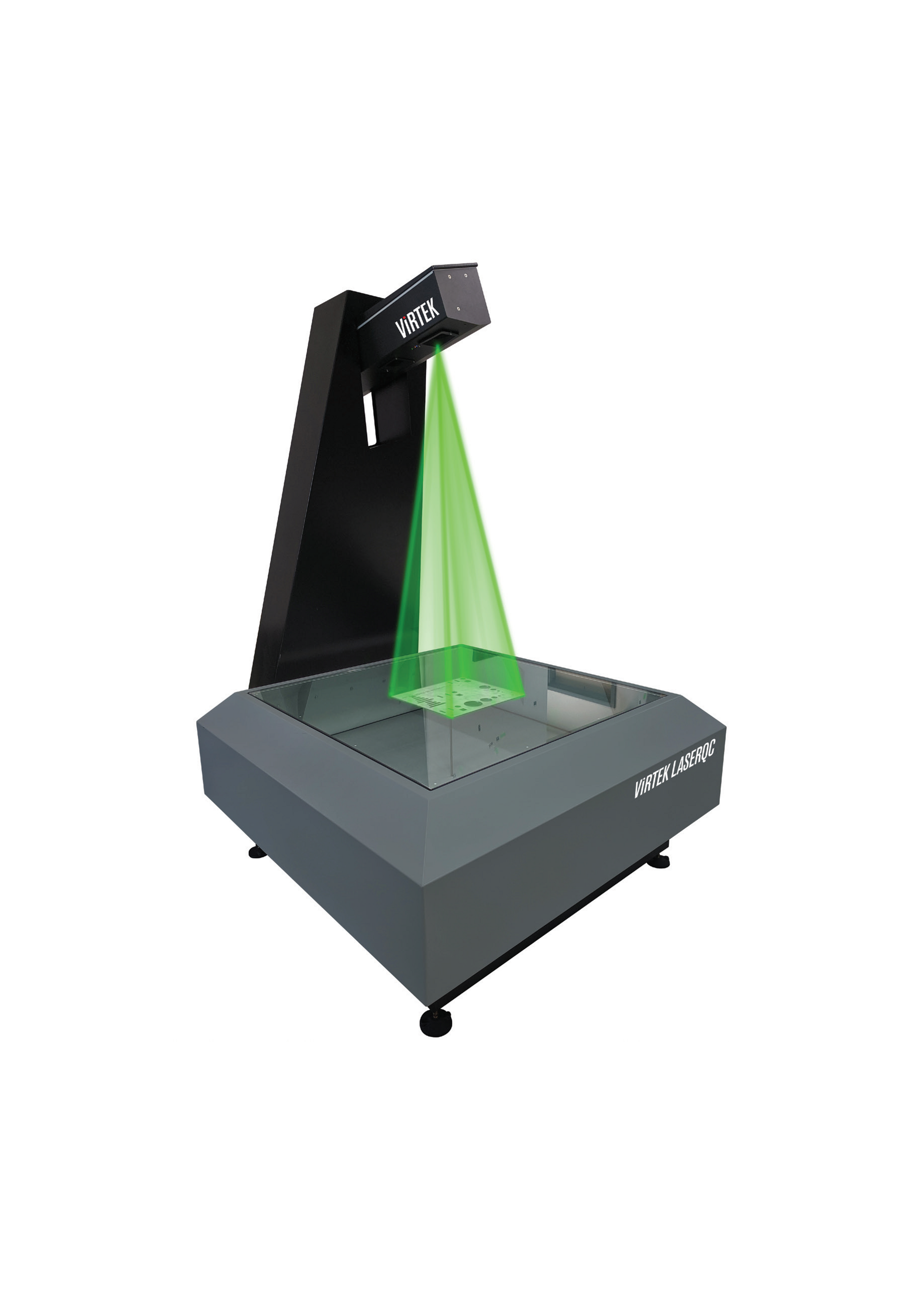

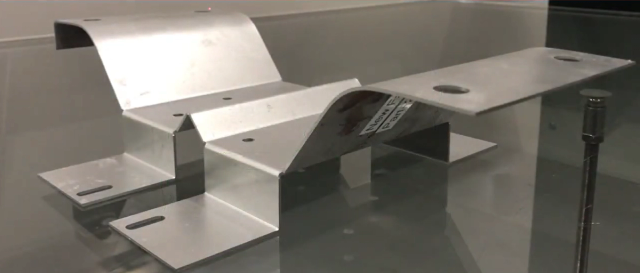

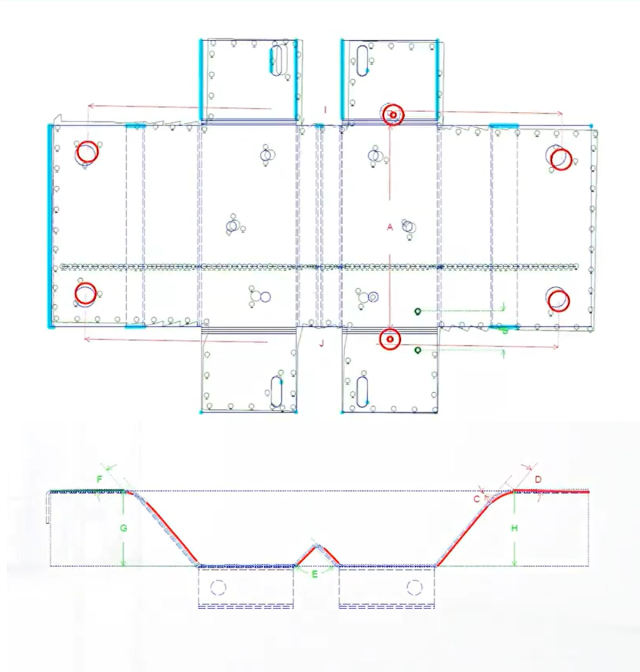

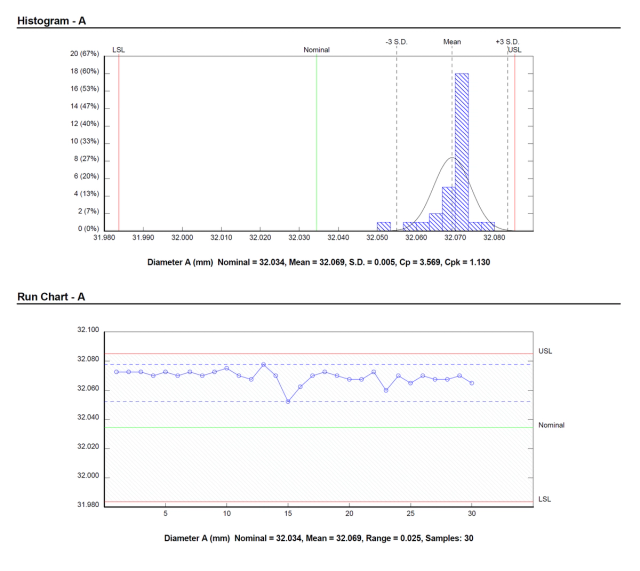

LaserQC® is the premier solution for 2D and 3D parts inspection. LaserQC® dramatically increases throughput in precision sheet metal, foam, leather, aerospace, and gasket fabrication. The system is designed for first article inspection, quality reporting (SPC, ISO, LEAN), reverse engineering and automatic formed measurement.

Laser Fast

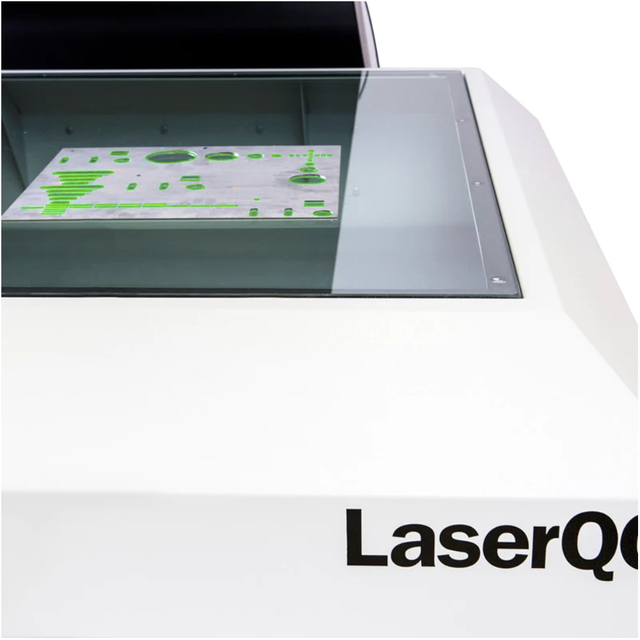

LaserQC® captures over 500 data points per second to make part inspections laser-fast, right on the shop floor. Designed to set up easily so your system is up and running in less than a day. The intuitive user interface allows new operators to become fully proficient within just a few hours.

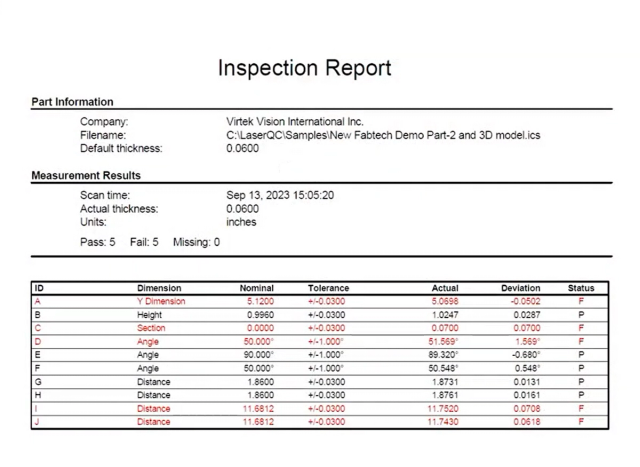

Laser Accurate

The system quickly performs 100% inspections accurate to ± 0.002” (0.05mm) for 2D measurements and ± 0.010” (0.25mm) for formed measurements.

Shop Floor Friendly

LaserQC® offers a reliable, low-maintenance solution that operates along side your facilities CNC equipment. The system self-calibrates and adjusts system settings to accommodate for environmental changes common to the shop floor. Additionally, Virtek offers a Part Stabilizer add-on, created specifically for use in the gasket and seal industries.