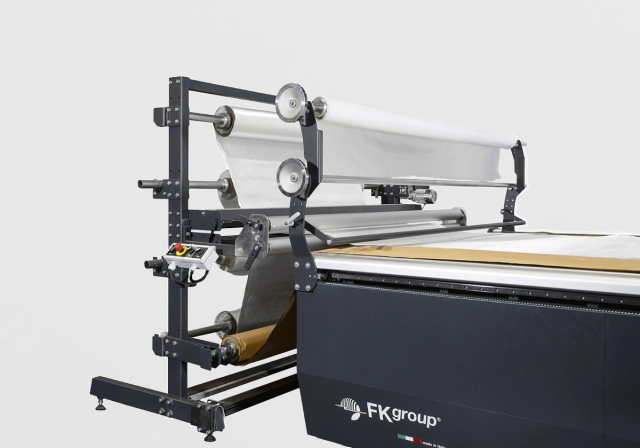

MULTI-ROLL FEEDER

The multi-roll feeder is an advanced solution for semi-stiff and technical fabrics that can be used effectively on any FKgroup cutting machine.

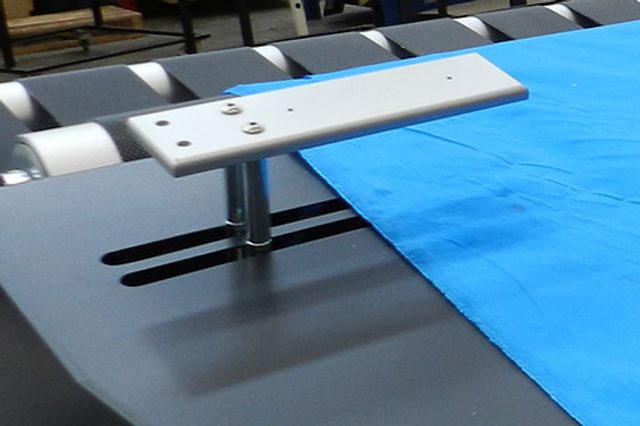

This innovative system is designed to improve cutting efficiency and precision.

The bar feed system is vertical and has four support brackets to house the rolls. The standard supply includes a set of four bars and related aluminium fixing cones that ensure stability and easy use. The sandwich mattress created is transported to the cutting system by means of an efficient two roll calender system that ensures uninterrupted and smooth flow of the materials.