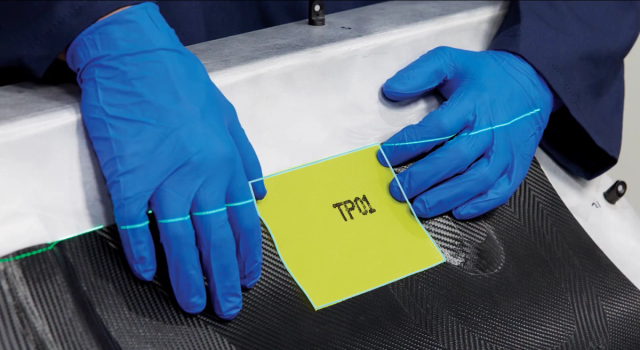

VIRTEK IRIS 3D laser templating and positioning systems accurately project a virtual laser template onto molds and parts to guide operators through the process of part fabrication whether it be ply layup, paint masking, assembly, or part placement.

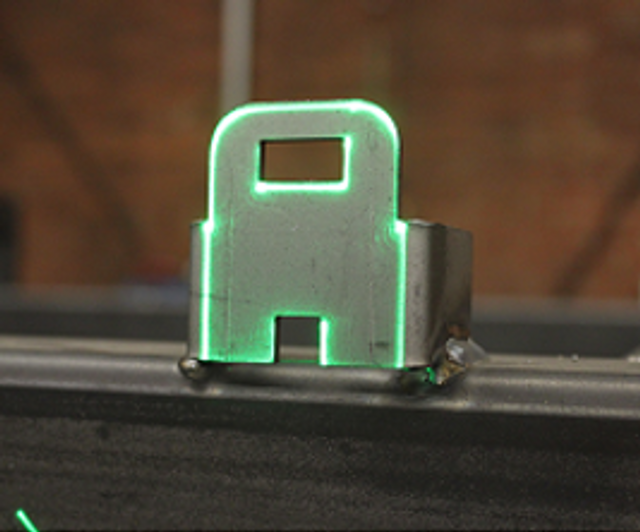

FlashAlign™

Instant alignment of the part or tool virtually eliminating set up time.

Multi-Tasking

Enables one projector to serve multiple workstations so ply layup on multiple parts can occur in parallel. The new thin client experience allows you to use one Iris 3D license to connect several PCs or tablets to serve as clients.

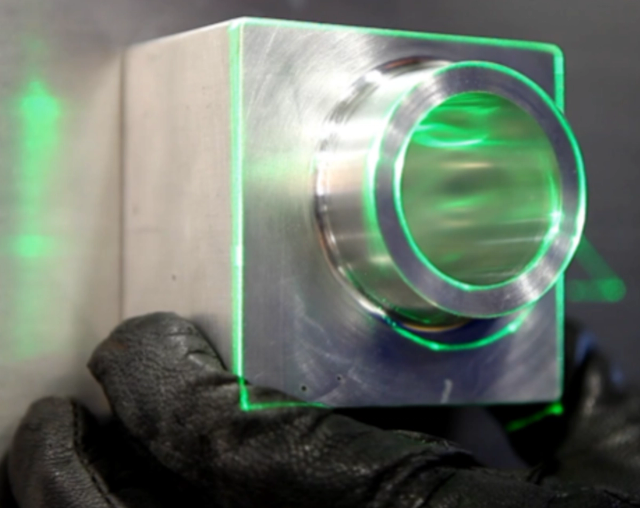

High Visibility

Provides operators with a brighter, safe laser delivering superior visibility even in the brightest work environments.

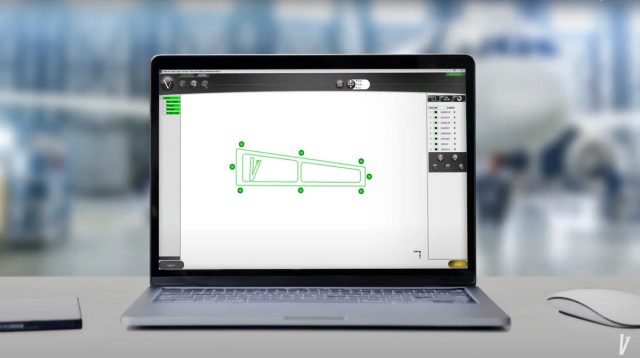

Simplified Software Interface

Reduced training & fewer operator errors, simplified operation and administration.

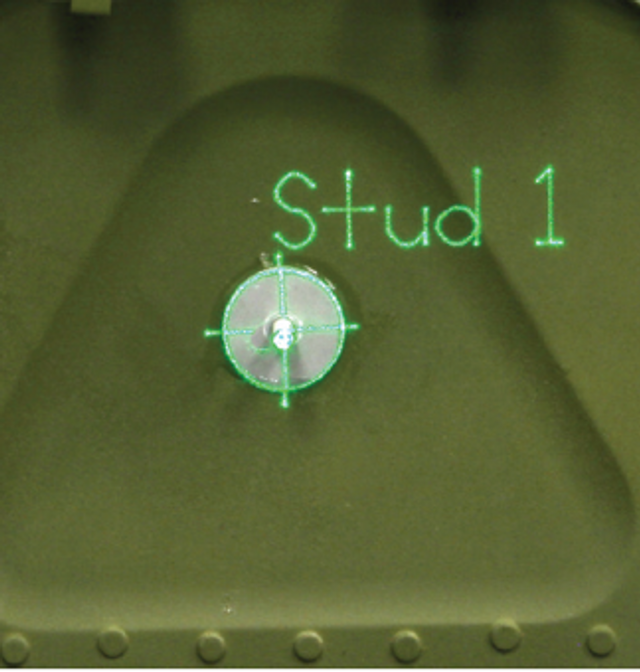

Projected Cross Hair

Automatically project crosshairs to indicate drill locations, punch locations, assembly positions. Crosshairs work on both flat and curved surfaces.